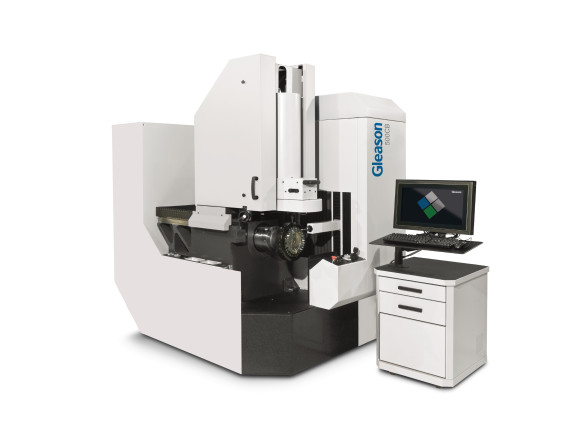

Phoenix 500C - Fast, Agile Production of Truck-Size Gears

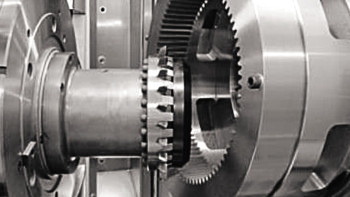

Gleason’s Phoenix® 500C Bevel Gear Cutting Machine has been designed to bring speed, flexibility and ease-of-use to medium and high volume production of precision bevel gears for trucks, buses, and other applications of similar size.

| Workpiece diameter, max. | 500 mm |

| Range of tooth numbers | 1-300 |

| Cutter diameter (FM), max. | 14" |

| Cutter radius (FH), max. | 210 mm |

Highly Versatile and Flexible

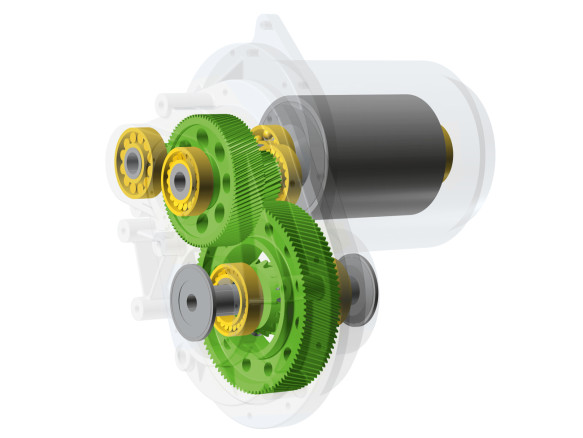

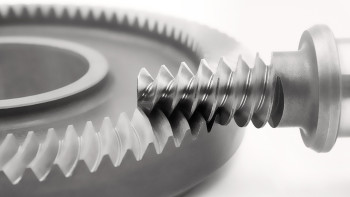

Gleason Phoenix machines can produce all types of face and straight bevel gears, SRH, Zerol®, spiral and hypoid gears, couplings and even straight bevel gears with front hubs.

Unmatched Speed and Productivity

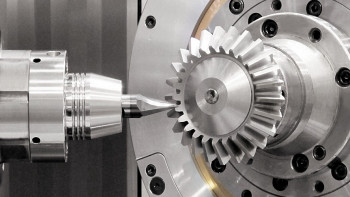

Machine motions are inherently shorter and faster with a design that puts cutter and workpiece in closer proximity.

High Static and Dynamic Stiffness

New column and slide design guarantees exceptional static and dynamic stiffness to meet high volume and precision requirements. The Phoenix 500C features superior protection of rails and ball screws, with robust, precision components throughout the machine.

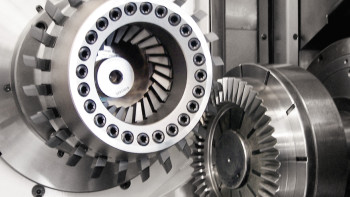

Integrated Chamfering

Serial chamfering of the heel can be performed optionally, well protected from the conditions during gear cutting.

Greatly Reduced Non-Productive Time

Chip-to-chip time is exceptionally low, with flexible robotic automation, facilitating loading/unloading of workpieces as heavy as 150 kg.

Integrated Automation

Available with Gleason stackable-tray and palletized automation solutions. Auxiliary processes can be added to meet specific requirements, including washing, laser marking, chamfering/deburring, and inspection.

Powerful Controls - User-Friendly Operation

GEMS machine operating software for easy setup and intuitive operation with network capabilities for fast integration into any modern production environment.

Ergonomic, User-Friendly Design

The machine design puts the operator at floor level with cutter head and workpiece, resulting in easy and convenient access to the workarea - no platform required.

GEMS On-Premise or in the Cloud: Gear Design and Optimization Anywhere, Anytime

GEMS® Gleason Engineering and Manufacturing System provides a complete smart factory solution to the gear industry by connecting system design, gear/tooling design, and manufacturing apps, optionally with cloud computing and mobile monitoring.