| Technology | Gear Machines, Tools, Workholding |

| Level | Basic, Advanced |

| Process | Gear Process Theory |

| Course Number | GHT-STWTCG-EN |

| Class Duration | 8h |

| Number of Participants | 50 |

| Training Location | Online, Munich, Germany |

69.00 EUR per session or 220.00 EUR for the entire seminar (4 sessions) plus VAT

69.00 EUR per session or 220.00 EUR for the entire seminar (4 sessions) plus VAT

Tools & Workholding for Cylindrical Gears

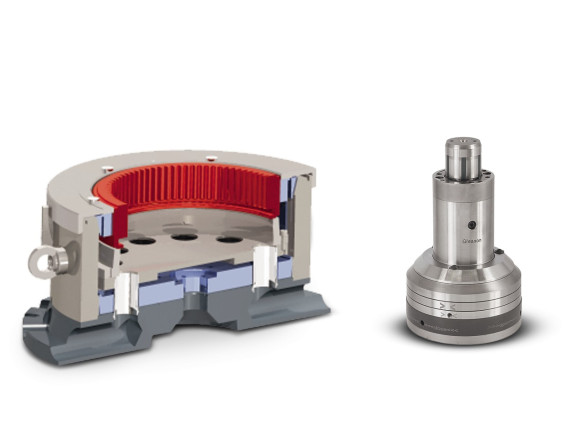

Gleason Seminars have been offered to the gear manufacturing industry for many years, with more than 2,500 participants up to date. The Seminar “Tools & Workholding for Cylindrical Gears” provides in-depth knowhow about cutting and hard finishing tools as well as workholding for cylindrical gears. In addition, participants learn about new technologies and tooling trends including latest smart tooling solutions. This seminar is primarily intended for gear manufacturing specialists in operations, work preparation and planning departments, who have basic knowledge and experience in gear manufacturing. The Gleason Tooling Seminar provides theoretical and practical input for efficient manufacturing strategies and processes. We look forward to meeting participants online and spending two valuable days.

1-day-classes are now split into 2 days with 4 sessions to support time management with participants’ regular day jobs. With each session participants will learn more about different aspects of “Tools & Workholding for Cylindrical Gears”. This Seminar is intended for “anyone” interested in learning more about the world of gears and the appropriate tools and workholding. This class is regularly attended by personnel involved in all aspects of gear manufacturing, including planning, purchasing, engineering, and manufacturing. Gleason experts from operations and global product managers guide participants through this online seminar and are available for live Q&A sessions.

Advantages

• Flexible participation from the workplace or home office.

• Optimized time management - each session 2 hours with one hour break

• Live Seminar: real trainers talk to you.

• No travel time and travel cost.

• Direct communication via audio and video with your trainer

• Digital training documentation.

• Certificate if all sessions of the seminar are completed.

Seminar schedule and topics

Session 1

• Current Trends and Developments in Soft and Hard Machining of Gears

• Tools for Soft Manufacturing of Gears

• Live Q&A

Session 2

• Carbide Tools – Potentials to Boost Productivity

• Hard Finishing Processes in Comparison

• Designing Honing and Grinding Tools

• Live Q&A

Session 3

• Economical Chamfering : Opportunities and Limits

• Workholding for State-of-the-Art Production Environments

• Live Q&A

Session 4

• Challenges in Gear Finishing Applications

• Gear Manufacturing in a Connected World (4.0 Solutions)

• Live Q&A

• Virtual Plant Tour and closing

Registration

The current dates of this Live-Seminar can be found under Events.