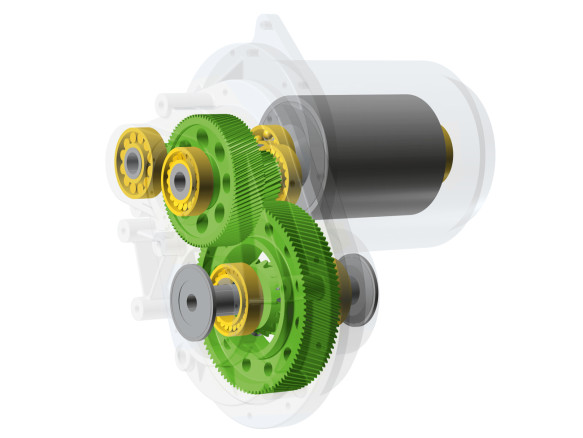

The New Compact Transmission with High Power Density

The new Diff2 transmission features a double differential: an outer differential unit wraps around a differential center unit. Both units rotate around the same axes with different speeds. Double tooth mesh and its symmetry of reacting forces makes the new Diff2 extremely compact and powerful.

Extremely High Ratios

The potential of double differentials as ultrahigh reduction speed reducers is incredible. Only the tooth-count of the gears in the outer differential unit has to be changed in order to achieve ratios between 5 and 80 without a noticeable change of the transmission size.

Very High Input RPM

Today’s electric motors for EVs have speeds of 10,000 to 20,000 RPM, with late developments increasing up to 40,000 RPM. Resulting transmission ratios are more than 20 times higher than in today’s transmissions for vehicles with combustion engines.

Store Kinetic Energy for Short Acceleration Bursts

The Diff2 allows the storage of kinetic energy during gentle driving periods as well as deceleration and breaking actions.

Design Configurations

A particularly interesting design configuration is the version with two inputs, making it possible for two electric motors or one electric motor and a combustion engine to feed into the transmission. This configuration achieves considerable energy savings under sporty driving conditions: energy is stored and fed quickly back during stop and go driving patterns.

Excellent Efficiency Due to 50% Sliding Reduction

Double differentials are well suited for high input speeds. The fact that the carrier rotates with about half of the input speed reduces the relative motion as well as the sliding velocity to 50% of the value of two conventionally meshing bevel gears which roll with the same input speed.

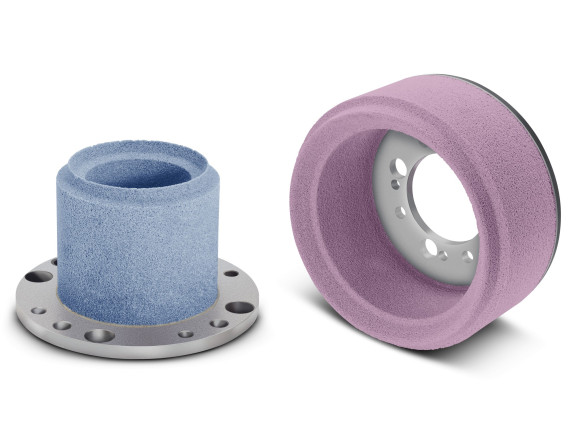

Easy to Manufacture and Assemble

The Diff2 is easy to manufacture and easy to assemble. Gleason does provide any necessary means for the design, manufacture and inspection of the required gears.