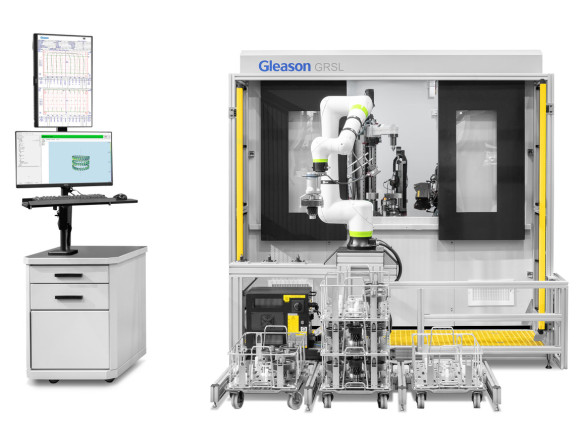

Integration of Pre- and Post-Processes

Gleason Machine Tool Loader Systems can be equipped with internal or external options for part material handling, processing, tracing, inspection, assembly, and many other pre or post secondary operations.

Internal or External Integration

Options are available for all models, either fully integrated or in connection with external equipment.

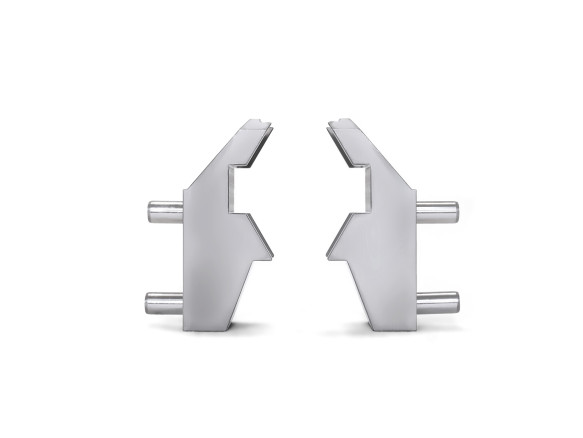

Error Proofing

Part type checking, part orientation and audit inspection.

Process Operations

Washing and drying, coolant flushing and blow off, hole blow out, coolant spin off, deburring (brushing or shot blast), metal cutting, rust prevention coating, draw heating, induction heating, UV curing, fluid dipping and filling, gluing, deflashing and degating.

Identification and Traceability

Laser marking, pin marking, hard stamp date coding, ink jet marking, ink daub marking, bar code labeling, reading marks associating data to factory information systems.

Inspection and Test Operations

Tapped hole thread checking, broken tool detection, eddy current heat treat checking or crack testing, leak or flow testing, dimensional gaging (static or dynamic), weld inspection, vision inspection, push or pull testing, surface finish inspection, functional testing, CMM audit inspection, weighing.

Assembly Operations

Feed and press components, feed and ultrasonic weld components, feed and rivet components, feed and fasten threaded components.