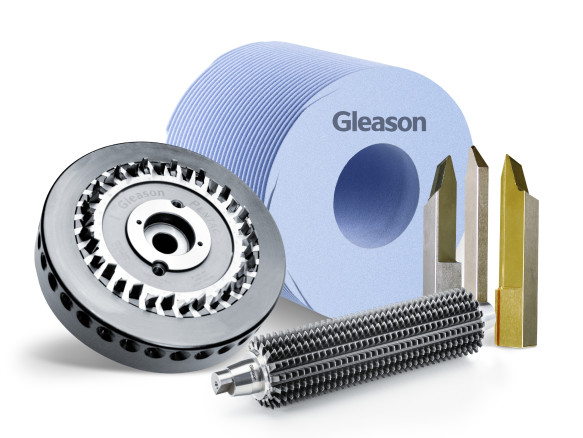

Tool Services - A Total Solutions Approach

Gleason offers customers a total system to maximize cutting tool performance. Use our e-Ticket Tooling for online tool requests. You will benefit from quickly and effectively support compared to telephone or e-mail requests.

Hob Sharpening

Gleason sharpens all kinds of hobs including HSS and carbide hobs, from fine to coarse pitch hobs, according to standard DIN classes or Gleason specification. Hobs resharpened by Gleason will compare to new tools in quality, tool life and performance.

Reprofiling Service

The advantage of reprofiling is 100% utilization of the tooth length, as well as the repair of damaged tool areas. This allows you to employ tools with maximum efficiency over their entire life.

Shaving Cutter Sharpening

Shaving cutters are reground on Gleason's renowned SRS and SCG Shaving Cutter Sharpening Machines providing the highest quality results. Shaving cutters are returned with the appropriate documentation and regrinding diagrams.

Power Skiving and Shaper Cutter Sharpening

Gleason's cutter sharpening service returns used shaper cutters and Power Skiving Tools to as-new quality levels based on our extensive expertise in shaping and Power Skiving applications.

Reconditioning of Master Gears

Gleason reconditions master gears to their closest tolerances, including masters for calibration, checking and testing. The close affiliation between our sister companies, Gleason Metrology Systems and Gleason-Hurth Tooling, provides us with state-of-the art equipment and the necessary insight to master even the most demanding task.

Coating Services

Gleason is keeping pace with record demand and shorter lead times. We are able to build on Balzers' proven coating technology, and take tool preparation and processing to a whole new level.

Express Tools - Also in Carbide

Whether prototyping, unforeseen bottlenecks, or urgent orders – there are many reasons that may result in enormous time pressure. Gleason express tools (including special profiles) are produced in just a few days.

High Performance Heat Treat

Heat treat capabilities to assure optimum metallurgical results, along with close control of distortion and dimensional change.

On-Site Metallurgical Laboratory

Metallographic sample preparation and evaluation. High magnification stereomicroscope or metallographic evaluation and photography.

Reconditioning of CBN- and Diamond-Plated Tools

Gleason provides reconditioning services for CBN- and diamond-plated grinding and dressing tools. Including the reworking of the tool bodies and replating in state-of-the-art facilities. Profile accuracy and surface quality are guaranteed to meet customer requirements in all types of grinding applications.

Pick Up and Delivery Service

Our pick up and delivery service is available in certain states in the United States. Contact our experts for further information.

Training Solutions

Gleason offers the industry’s widest variety of training courses, covering the full spectrum of cylindrical and bevel gear topics, from gear design to quality control of the final product.