Mar 19, 2013

BTPL- Chennai is a 100% owned subsidiary of the Bonfiglioli Group of Italy, having a state-of-the-art manufacturing facility at Chennai, India. Serving both domestic and international markets, BPTL produces industrial power transmission products in their two Chennai facilities. Products include industrial speed reducers, fixed speed gear motors, electric motors, mechanical speed reducers, electric drives and applications. Their latest product line addition includes gear boxes for mobile equipment such as cranes, lifts, and material handling devices, and for mobile machinery and construction applications. Customers include companies like John Deere, JCB and several others. BPTL’s total employment in the two Chennai based facilities is approximately700 people.

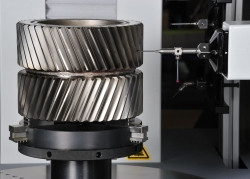

Bonfiglioli became a customer of Gleason Metrology Systems in early 2006. At that time Bonfiglioli purchased 3 Sigma model machines, destined for various locations in Europe and India. For India the goal was to achieve higher throughput, additional capacity and more reliable localized services in this new and growing market. To help achieve this, the Chennai facility in 2008 purchased an additional Gleason Gear Inspection machine equipped with the new GAMA suite of applications software for the parts Bonfiglioli produces. This windows based platform incorporates a great ease of use of all measuring programs and is the preferred machine of operators in the plant. Bonfiglioli is currently considering an upgrade of their model Sigma 7 to the Windows® based GAMA suite and Renishaw gaging system.

The Bonfiglioli Chennai plant produces spiral bevel, helical bevel, worm and large module cylindrical gears in their factory in Chennai, for which the gears require inspection for helix, profile and index - pitch analysis, to many industrial standards. They also use the Gleason Metrology Systems inspection machines to quantify the various cutting tools required to produce this wide variety of gears. Since their installation several years ago, the machines have operated without interruption and receive regular support from the Gleason Works India and via GleasonConnect, an internet based service support system offered by Gleason to its global customer base. Bonfiglioli has used this service on different occasions to add measurement capability and receive technical support in short order to keep the machines operating, and providing valuable inspection results.

“Overall, the Bonfiglioli team is happy with the performance of Gleason inspection systems, and they serve our purposes very well. We have seen significant improvements from SIGMA 7 to the 650GMM version with the new GAMA software & Renishaw 3 D Scanning probing system which provides greater accuracy with high deflection ranges on all 3 measuring axes. Specifically, this probing system allows us the flexibility to measure high crowning parts of maximum +/- 1000 microns on our most demanding work-pieces.” States Mr. Kennady, Chief Operation Officer, Bonfiglioli Chennai.

Mr. Kennady also states: “We feel that in a short period of time, Gleason has made improvements in the software, and gaging systems, and in the 650GMM, the SPC analysis is very useful for our internal analysis purposes”. Currently we are using Gleason gear inspection and analysis systems to develop our new mobile gear boxes for JCB, John Deere and wind turbine gearbox components.”

If your gear manufacturing facility is in search of unparalleled inspection flexibility, high accuracy and strong domestic support in the Indian market, please contact our Gleason India sales team through one of many local offices strategically placed throughout India.