Genesis 400H(CD) - The Productivity Master with Optional Flexible Chamfering

The Genesis® 400H(CD) Hobbing Machine is designed for many different applications like disc- or shaft-type spur or helical gears, skive hobbing of hardened gears or cutting of special profiles. Whether small batch manufacture or mass production, the Gleason Genesis 400H(CD) can be configured to all your requirements.

| Workpiece diameter, max. | 400/450* mm |

| Module, max. | 8 mm |

| Axial slide travel, max. | 650 mm |

| * Option |

Designed Especially for Dry Hobbing with the Option for Wet Hobbing

Clean, uncluttered workarea to contain cutting debris and to divert chips effectively.

Parallel Chamfering/Deburring via Highly Flexible Fly Cutter Chamfering (Contour Milling)

Gleason Fly Cutter Chamfering creates a defined chamfer on the gear tooth while keeping tool availability and cost at the minimum. Only a few cutter insert sizes cover a wide range of chamfer types.

Full Control of The Chamfering Process

Chamfer sizes and angles can be flexible and easily defined via the Gleason Operator Interface.

Fast Changeover - Longer Parts

Optional CNC controlled tailstock for fast changeover and axis travel of 650 mm for cutting long shafts.

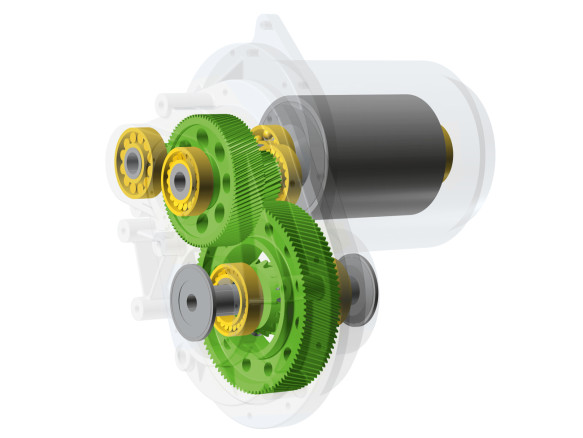

Convenient Setup and Fast Tool Change

Gleason Workholding Solutions are available in hydraulic and manual executions featuring convenient setup and fast tool change.