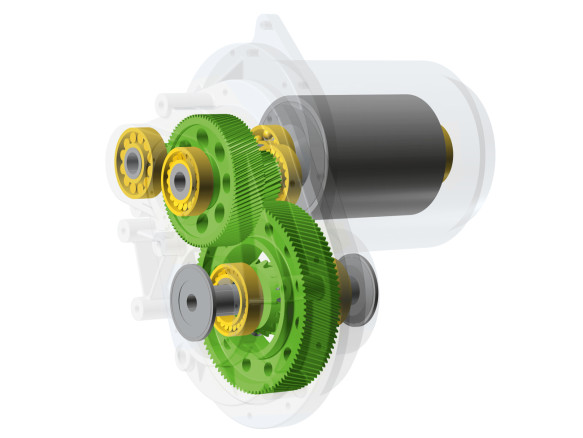

High Precision Gears for EV Gearboxes

Gleason offers hobbing, Power Skiving, and gear honing machines, with integrated auxiliary processes like chamfering, to cut and hard-finish your high precision EV transmission parts, including gears, pinions, geared shafts, and even demanding stepped pinions.

High Speed Hobbing with Integrated Chamfering/Deburring

Gleason features a complete line of hobbing machines for high speed cutting of EV gears and geared shafts with carbide and HSS tools, dry or wet, with integrated chamfering processes: chamfer rolling, chamfer cutting, as well as brand-new radial chamfering.

Power Skiving for Workpieces with Interfering Contours

Power Skiving is perfectly suited for the economical production of EV gears with interfering contours and internal gears, as well as shaft-type parts. Power Skiving machines are available in different executions, including optional hobbing, extended workpiece ranges, or even integrating tool resharpening.

Polish Honing and Combi Honing

Gleason offers specific honing strategies for gears and shafts, including large and heavy workpieces, or small and complex applications. Combi Honing allows the finishing of two gears on a workpiece in a single setup, ideally suited for e-Drive step pinions even with tight timing tolerances.

Polish Grinding or Fine Grinding

Create gears with a quality surface finish by using two-zone grinding wheels for grinding and polishing/fine-grinding, matching the individual requirements of each process. Additionally, the GX-series of threaded wheel grinding machines is loaded with a wealth of technology features.

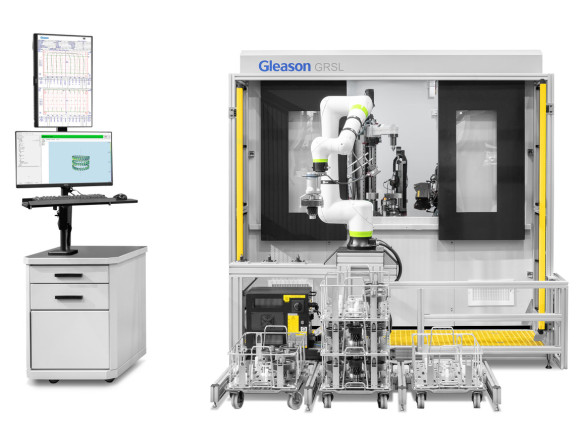

Revolutionary In-Process Laser Inspection

The GRSL provides optical pitch, lead and profile inspection for all teeth on a workpiece, as well as dual flank rolling testing including inspection for tooth flank damage, total dual flank working deviation and dual flank working error, functional runout, DOB measurement, average tooth thickness and more.