GRSL - Dual Flank Rolling Inspection Combined with Advanced Laser Technology

GRSL (Gear Rolling System with Integrated Laser Technology) combines dual flank rolling inspection with advanced non-contact laser technology in a single system. Cycle times for optical pitch and profile inspection are reduced to a few seconds, enabling 100% analytical inspection of applications with very high demands.

| 工件直径, 最大 | 250 mm |

| 模数, 最大 | 7.2 mm |

Exceptionally Fast and Powerful Non-Contact Inspection

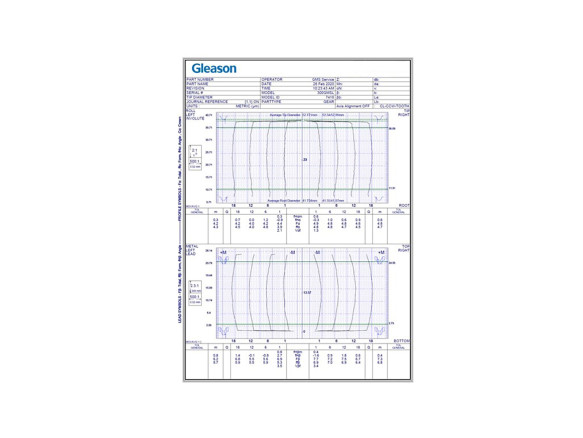

The GRSL provides optical pitch, lead and profile inspection for all teeth on a workpiece, as well as dual flank rolling testing including inspection for tooth flank damage, total dual flank working deviation and dual flank working error, functional runout, DOB measurement, average tooth thickness and more.

广泛用于各种外圆柱齿轮

可以采用手动,半自动或者全自动配置

大批量快速测量能力

在同一个测量循环中实现啮合分析和齿形分度的测量

自动化,在线。齿轮测量和机床闭环反调功能

GRSL 系统实时显示数据展现加工过程的变化趋势。结果可以在线返回到部份格里森机床,进行闭环机床反调。可以集成其它工序,如清洗,打标,以及硬度测量等。

Be Fully Compatible

GAMATM 3.1 or 3.2 Applications and Control Software is fully compatible with Windows and connects easily to customers' servers. GAMA includes SPC data acquisition software and Gleason Connect® Global Support Services.

Dual Flank Rolling System with Laser Scanning

Dual flank rolling testing and dual flank working deviation as well as pitch, lead and profile inspection, all performed simultaneously.

Fully Integrated in the HFC

The GRSL is the central component in the world’s first in-process hard gear finishing cell, the HFC.